Workplace safety is essential no matter your industry, including house painting in Dublin, CA. The chief goal of a company’s safety program is to minimize the risk of illness, injury, or fatality to workers. Additionally, a safe work environment can help minimize stress and anxiety and maintain overall well-being for the workers.

Complying with industry safety standards should benefit a business in many ways, aside from ensuring the safety of the workers. This also includes prevention from potential lawsuits and paying legal fees. When the workers are protected and safeguarded, they will be able to work more effectively, leading to higher productivity and overall job satisfaction.

Any responsible paint service company provides safety gear and complies with the industry safety guidelines while they are at the work site. This article aims to provide a comprehensive guide to safe painting practices.

Understanding painting hazards

Many people believe that painting is a straightforward job. However, it comes with many risks:

- Prolonged standing

- Working at heights

- Slips and falls

- Exposure to chemicals and sanding dust

- Exposure to sanding dust

- Exposure to mold and mildew spores

- Working in confined spaces

- Improper ventilation

- Exposure to heat and cold

- Falling objects

- Lifting heavy or awkward objects

- Repetitive strain injury

- Electrical hazards

- Lack of proper ventilation

- Working in confined spaces

- Injury from using sharp tools or contact with rough surfaces, etc.

- High-frequency noise (more common in commercial and industrial paint projects)

Ignoring safety measures in the workplace can lead to a range of serious consequences. These can affect not only the individual employees but also the organization. Here are some of the key consequences of neglecting workplace safety:

- Injuries and fatalities – The most immediate and severe consequence is the increased risk of accidents leading to injuries or fatalities. This can range from minor injuries to life-altering conditions or even death.

- Health issues – Long-term exposure to hazards without adequate protection can lead to chronic health problems. This includes respiratory issues, hearing loss, musculoskeletal disorders, and even long-term illnesses like cancer from exposure to carcinogens.

- Legal and financial penalties – Organizations that fail to adhere to safety regulations can face substantial legal consequences, including fines, penalties, and lawsuits. In some cases, there might also be criminal charges if negligence is found.

- Increased workers’ compensation claims – An unsafe work environment leads to more accidents and injuries, which in turn increases workers’ compensation claims. This can significantly increase the operational costs for a business.

- Reduced productivity and morale – Employees who feel unsafe at work are likely to be less productive and engaged. This can lead to higher turnover rates, absenteeism, and a general decline in morale.

- Damage to reputation – Workplace accidents, especially those that could have been prevented, can damage an organization’s reputation. This can lead to a loss of business, difficulty in recruiting skilled workers, and a negative public image.

- Psychological impact – Accidents and unsafe working conditions can have a psychological impact on employees, including stress, anxiety, and post-traumatic stress disorder (PTSD), especially if they or their colleagues have been involved in serious accidents.

- Operational disruptions – Accidents can cause disruptions in operations, leading to downtime, loss of productivity, and, in some cases, the shutdown of entire operations for investigations and safety reviews.

- Cost of equipment damage – Accidents in the workplace can also lead to damage to machinery and equipment, adding additional costs for repair or replacement.

- Increased insurance premiums – A poor safety record can lead to higher insurance premiums as the risk of future claims is deemed higher.

- Deterioration of employer-employee relationship – Neglecting safety can lead to a breakdown in trust between employees and employers, which can negatively impact the workplace culture.

- Regulatory scrutiny – Companies with poor safety records may face increased scrutiny from regulatory agencies, leading to more frequent inspections and audits.

The consequences of neglecting workplace safety measures are multifaceted and can have lasting impacts on both the individual and organizational levels. Thus, prioritizing safety is not only a legal and ethical obligation but also a practical necessity for the sustainable operation of any workplace.

If the workers are unprotected at work and are not given the proper safety training and equipment they need, how do you expect them to want to work hard for you?

Whether doing residential, commercial, or industrial painting, the paint crew should be protected at the workplace. Here are some of the following key areas of painting where safety is crucial:

- Proper ventilation is critical, especially if you must use solvent-based paints in a small space. Make sure that ventilation is sufficient to allow the paint fumes to dissipate. If you’re painting in a confined area, open the door and windows (if any) and turn on fans to let the paint fumes out and the fresh air in.

- Some paints, primers, thinners, etc., are extremely flammable. To prevent the possibility of a fire incident, remove any ignition sources (open flame, welding, lights, smoking, etc.) until the fumes dissipate.

- Invest in personal protective equipment or PPE such as overalls, gloves, eye protection, hard hats, respirators, etc.

- Painters should be tethered to harnesses, anchors, and lifelines when painting above ground to ensure they won’t fall to the floor or ground if they slip or trip.

- Before working at heights, check your ladder, scaffolding, mechanical lift, or any other raised platform for defects.

Safe preparations before painting

- It’s important to assess the work environment for potential hazards. For instance, if the building you’re assessing is of considerable age, its current paint may contain lead, or the popcorn ceiling may contain asbestos – both lead and asbestos are toxic. If the building is tested and confirmed to have lead or asbestos, it requires proper and safe removal and disposal of such paints before a new painting job begins.

- Plan and set up a protected workspace – this is crucial for a safe paint job. The work area should be kept well-ventilated by opening doors and windows and turning on exhaust fans. Remove all furniture and decor to allow more elbow room for the paint crew. Turn off the main power before removing the switch and outlet cover plates and covering all exposed electrical outlets with painter’s tape. Use the safest possible paint products and other supplies, preferably the ones with a low or zero VOC content.

- Besides selecting the safest possible paints and other coatings, selecting the right tools and equipment with the right features is also crucial for a safe paint job. Investing in quality tools will help you deliver a smooth and safe paint job.

Personal protective equipment (PPE) for painters

Personal protective equipment (PPE) is a vital aspect of keeping residential and commercial painters safe for many reasons:

- Several types of paint and other supplies usually contain harsh chemicals that can cause significant health problems from long or constant exposure over time. These health problems range from skin allergies to respiratory problems to certain cancers.

- Sanding dust can get into the eyes, nose, and mouth, which can cause potential health issues such as eye irritation, respiratory problems, mucosal and non-allergy respiratory symptoms, and even cancer (especially when exposed to it frequently or for long hours).

- The use of certain tools, equipment, and machinery can cause abrasions and cuts.

- Working at heights can put the painters at great risk of falling.

- Dropping objects can cause injuries to painters, especially if they paint in a busy construction area.

- Some machinery can cause high-frequency noise. Painters working near such machinery can suffer from temporary or permanent loss of hearing without protection. This is more common in commercial and industrial painting.

Thus, the PPE is designed to protect the crew working with paint, primers, varnishes, thinners, wood stains, and other things they may usually deal with, like cleaning products, sanding dust, and certain tools and machinery.

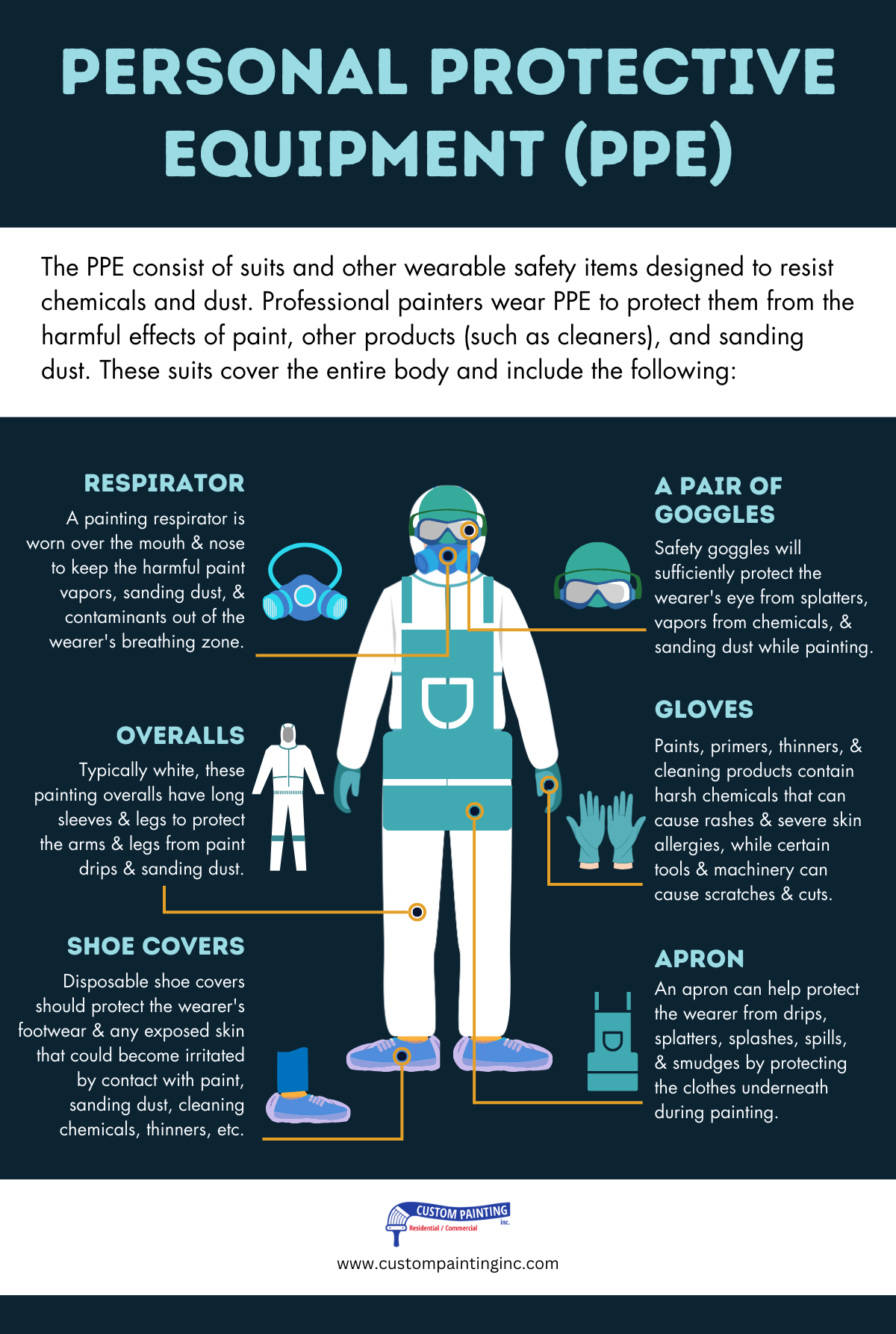

The PPE consists of protective suits and other wearable safety items. The PPE is worn by professional painters to protect them from the harmful effects of paint, other products (such as cleaning products), and sanding dust. These suits cover the entire body and include the following:

- Respiratory protection – The right respirator for painting jobs depends on the type of paint or other coating the painters use, the application method, and the level of ventilation in the work area. But for most painting jobs, a half-face air-purifying respirator with N95 or P100 filters should be enough to protect the wearer while painting.

- N95 respirator – N95 respirators typically filter out 95% (or greater) of airborne particles and contaminants, including sanding dust, mold spores, and paint fumes. They are ideal for most paint jobs, including brushing, rolling, and spraying paint water-based paints such as latex and acrylic.

- P100 respirator – P100 respirators typically filter out at least 99% of airborne particles. They are ideal for using oil-based (alkyd) paints and for painting enclosed spaces with inadequate ventilation.

- Powered respirator – This respirator filters and even purifies the air. It uses a pump to push the air into the hood the user wears.

- Eye, face, and head protection

- Safety glasses – Safety glasses usually have side shields to protect the eye area from fumes, contaminants, and flying-object hazards such as floating sawdust. Many safety glasses are tinted for protection against glare and the sun’s UV rays. They can also be worn over prescription glasses.

- Goggles – A good pair of goggles is a good option where there is a risk of paint, other chemicals, and sanding dust getting into the painter’s eyes, especially while spraying paint or painting in a windy or dusty environment. Goggles are also available in tinted options to protect the eyes from glare and the sun’s UV rays.

- Face shield – Face shields are usually worn for painting jobs where there is a risk of paint, other chemicals, and sanding dust getting into the painter’s eyes, especially while spraying paint or painting in a windy or dusty environment. However, wearing a face shield alone doesn’t guarantee complete protection for the face from such contamination, so it should be worn over protective eyewear and/or face mask.

- Hard hat – A hard hat protects the wearer’s head in the event of a possible impact caused by a falling object or collision during a fall.

- Protective clothing

- Overalls – Overalls usually consist of a pair of trousers with a bib, holder, and loose straps to wear over the painter’s normal clothes. Unlike coveralls, overalls do not usually cover the arms and the head. Overalls are ideal for light paint jobs or for indoor painting where the painter isn’t exposed to sunlight and other harsh weather elements.

- Coveralls – Overalls have long sleeves and legs to protect the arms and legs from paint drips and sanding dust and a hood to protect the head from paint drips and splatters.

- Apron – An apron protects the wearer’s clothes underneath it from drips, splatters, splashes, spills, and smudges while painting.

- High-visibility safety vest or jacket – Painters working at heights should wear a reflective safety vest or jacket for visibility and protection from potential hazards. These vests allow the worker to be seen and alert that someone is present, especially in low-visibility situations.

- Hand and foot protection

- Gloves – Protective gloves for paint jobs are available in coated, foam, nylon, cut-resistant, and nitrite, reusable, and disposable options. Whatever type of protective gloves are chosen, they are all essential for protecting the painter’s hands from paint drips and splatters, sharp or rough objects, abrasion hazards, cold and heat, and potential injuries.

- Shoe covers – Shoe covers keep dirt and grime from entering the worksite, and the additional benefit is protecting the painter’s footwear from wet paint.

- Safety shoes – The choice of safety shoes depends on the present or potential hazards. It’s a good idea to assess the workplace and work activities of the painters. However, all safety shoes for the workplace should be slip-resistant and sufficiently protect the feet from punctures, cuts, falling objects, injuries, etc. Painters who are exposed to high temperatures on a regular basis require a pair of shoes that can withstand extreme heat. High-cut safety boots are good for most workers, particularly those who are exposed to rough or damp environments. They also help keep the feet comfortable, clean, and dry.

- Fall arrest equipment –

- Full-body harness or safety harness – It is a wearable fall arrest component that connects the wearer to the anchorage point, preventing that wearer from hitting the floor or ground in the event of a fall. Unlike a mere safety belt, a full-body harness distributes all forces of a fall onto one area of the wearer’s body, ensuring that the wearer is suspended upright right following a fall.

- Connectors – Connectors or connecting means serve as a bridge between the full-body harness and the anchorage connector. They usually consist of energy-absorbing components to prevent injury during a fall. Some connectors feature a control system that enables the wearer to adjust the line as necessary. In addition, connectors include backup webbing and clips that connect the lanyard to the full-body harness. Some connectors include:

- Lanyard – A lanyard connects the full-body harness to the anchor or lifeline with a line of energy-absorbing webbing.

- Lifelines – Self-retracting lifelines feature an automatic belay system that maintains constant tension on the line. The rope, cable, or webbing retracts into the housing unit connected to the anchorage.

- Carabiners – A carabiner is a coupling link with a safety closure. Carabiners can serve as a good backup system and provide extra security.

- Webbing – Webbing is a material that provides a strong but flexible backbone of a harness and ties all weight-bearing parts (belt, leg loops, belay loop) together. Traditionally, the webbing has been made from nylon, polyester, or other synthetic fibers.

- Hearing protection – The Occupational Health and Safety Administration (OSHA) requires employers to implement a hearing conservation program when exposure to noise is at 85 decibels or greater, averaged over eight work hours or an eight-hour time-weighted average (TWA). In addition, the agency also requires employers to provide hearing protectors available to all employees exposed to such high-frequency noise over eight working hours or an eight-hour TWA, free of charge. Hearing protection equipment shall be replaced as necessary.

- Safety earplugs – Earplugs are inserted into the ear to prevent loud noise from entering the ear. They are also useful to protect the ear from the intrusion of water, dust, insects, cold, and strong winds.

- Earmuffs – They are used to protect the wearer’s ears from excessive noise, as well as dust, or extreme temperature changes. If the noise levels are too high or if a person has very ears, earplugs and earmuffs can be worn together.

Safe handling of paint and chemicals

The chemicals in paint, thinners, wood stains, primers, etc., can cause both short- and long-term health effects. Inhaling paint fumes may cause some people to experience headaches, dizziness, nausea, and breathing problems. Splashes of paint or chemicals can cause eye injuries and skin irritation without proper protection.

Naturally, commercial and residential painters deal with paints and other supplies. Frequent or prolonged exposure to paints and other related products can cause them to suffer from long-term illnesses – such as respiratory problems, impaired kidneys, and certain cancers – if proper protection is not used and safety measures are not followed.

That’s why safe handling of paints and chemicals is crucial to protect the painters from bodily harm.

When painting indoors, the area should be kept well-ventilated by opening doors and windows as well as running exhaust fans to let the chemical fumes out and the fresh air in. And, of course, the workers should wear PPE.

Instead of using traditional latex or oil paints, use paints with low-VOC or zero-VOC formulas. So-called “green paints” or eco-friendly paints that emit very little to noxious fumes are available.

After painting is done, the paints should be cleaned up and disposed of properly. But if you want to keep the paints, store them in a cool, dry place and out of direct sunlight. Make sure the paints are out of reach of pets and children and away from food, drink, and ignition sources. Store leftover latex paints in lined metal cans, glass, or plastic containers.

Ladder and scaffolding safety

For painting at heights, here are some general safety measures to help painters use ladders and scaffolds safely when painting a house or commercial building:

- Inspect ladders and scaffolds regularly for cracks or broken joints before using them.

- Place ladders or install scaffolds on stable, flat, and even surfaces. Do not mount a ladder on top of another object.

- When using the ladder, keep both feet on it. Do not put one foot on a rung and the other on a different surface.

- Always face the ladder when climbing or descending.

- Ensure that supported scaffolds have proper access, completely planked platforms, complete guardrails, and appropriate ties to buildings, where required.

- Leave a scaffold’s wood planks unpainted so that any cracks or holes will be visible.

- Place scaffolds at least 10 feet from power lines (unless the power lines are de-energized).

- Do not work on a ladder or scaffold in high winds or during a storm

- Protect workers below the scaffold. A toe board should be placed below the scaffold to prevent objects from falling off it. If objects on a scaffold are taller than the toe board, debris nets should be installed below the scaffold to catch falling materials. People should be forbidden from walking under or near the scaffold.

- The employer should provide training for any worker who assembles, disassembles, moves, operates, repairs, inspects, or maintains scaffolds.

Ergonomics in painting

Ergonomics is designed to make the work safer and more efficient. In any profession, implementing ergonomic solutions is essential to make workers more comfortable so that they will become more productive. Ergonomics can help reduce pain and possible injuries, making work more comfortable for every individual worker.

Painting a home or commercial building requires physical effort. Painters do various tasks – painting with brushes or rollers, sanding, mixing paint, climbing up and descending from a ladder, and a lot more. Many of these tasks include awkward postures, repeated movements, and forceful extensions that contribute to the development of physical discomfort and pain, such as musculoskeletal disorders (MSDs).

Painters should consider the following tips to minimize such physical strain at work:

- Recognize the early signs of musculoskeletal disorders such as aches, pains, weakness, numbness, and loss of strength. It will enable you to take preventative measures (such as doing stretches, changing your posture or position, or consulting a physician, etc.) to prevent MSDs from developing.

- Avoid bending at the waist for prolonged periods, especially when lifting or lowering objects. Bending forward for prolonged periods is a considerable risk factor for back injuries because doing so will strain the spine and its surrounding soft tissues. Here are some tips to reduce such strain:

- When possible, raise your work on a bench or two sawhorses.

- Sit on a stool for a prolonged period of working on lower levels. This can minimize some of the stress on your back from bending forward and the stress on your knees from squatting.

- Whether working on heights or working on the ground, do not place or store materials on a ground or floor level. You must have an elevated surface to place your paints and tools, preferably at waist height, so you won’t have to bend forward repeatedly.

- Minimize overhead work whenever possible. Overhead lifting and reaching can cause the back to arch, and excessive arching can place considerable stress on the spine’s joints and put additional strain on the shoulders and neck.

- If you must work overhead, get to your work as close as possible by standing on a ladder or any other elevated surface.

- Take breaks more frequently.

- While painting above the shoulder level, use a ladder or any other elevated surface so that your back won’t over-extend.

- When painting overhead, use stable extensions for painting equipment, such as a metal telescoping pole, instead of plastic ones for paint rollers.

- Place your can or bucket of paint on a table or any other elevated surface at waist height.

- Kneel instead of bending while painting. When kneeling, protect your knees by wearing knee pads or wearing pants with built-in knee pads.

- Take a break every two hours. Do some stretches, walk around, and change your posture or position.

Safety in elevated and confined spaces

Painting in elevated and confined spaces presents unique challenges for the painters.

Painting is already challenging, and adding extreme heights and confined spaces to the equation can make the job even more dangerous. This is why the use of fall protection systems and proper ventilation is vital to the painter’s safety.

When working above ground level, a painter should wear the following for protection:

- Full-body harness or safety harness – It is a wearable fall arrest component that connects the wearer to the anchorage point, preventing that wearer from hitting the floor or ground in the event of a fall. Unlike a mere safety belt, a full-body harness distributes all forces of a fall onto one area of the wearer’s body, ensuring that the wearer is suspended upright right following a fall.

- Connectors – Connectors or connecting means serve as a bridge between the full-body harness and the anchorage connector. They usually consist of energy-absorbing components to prevent injury during a fall. Some connectors feature a control system that enables the wearer to adjust the line as necessary. In addition, connectors include backup webbing and clips that connect the lanyard to the full-body harness. Some connectors include:

- Lanyard – The lanyard connects the full-body harness to the anchor or lifeline with a line of energy-absorbing webbing.

- Lifelines – Self-retracting lifelines feature an automatic belay system that maintains constant tension on the line. The rope, cable, or webbing retracts into the housing unit connected to the anchorage.

- Carabiners – A carabiner is a coupling link with a safety closure. Carabiners can serve as a good backup system and provide extra security.

- Webbing – Webbing is a material that provides a strong but flexible backbone of a harness and ties all weight-bearing parts (belt, leg loops, belay loop) together. Traditionally, the webbing has been made from nylon, polyester, or other synthetic fibers.

- Lanyard – The lanyard connects the full-body harness to the anchor or lifeline with a line of energy-absorbing webbing.

One of the challenges of painting in confined spaces is the significant lack of ventilation. Paints, thinners, primers, industrial solvents, and other substances may emit chemical vapors that can reach dangerous levels in such a small space. Here are a few tips to make painting in confined spaces more safely:

- Open the door and windows (if there are any) to allow proper airflow.

- Use a fan to drive the paint fumes away from where you’re painting and toward the door or window.

- Use a respirator, such as the N95 mask, specifically designed to lower your risk of inhaling VOCs, and a pair of goggles to prevent the paint fumes from getting into your eyes.

- Choose a zero-VOC paint. Or better, choose “green paints,” which are non-toxic and biodegradable paints that use natural compounds and minerals.

Creating a culture of safety

Painters do other tasks than just painting. Plus, they work in different environments, and often, these environments can put their health and safety at risk. That’s why it’s essential to maintain their own safety wherever they work. One of the ways to do that is to undergo safety training and awareness, and every responsible employer should provide that to their workers.

When painters are trained to work safely, they will be able to anticipate job-related hazards to avoid accidents effectively. Safety awareness training is crucial for the paint crew, and training should be directly applicable to their responsibility and everyday tasks.

If a company implements safety protocols and procedures in the workplace, it will be able to protect its crew and its brand reputation. Enforcing safety rules and regulations can reduce the risk of accidents and injuries, boost workplace morale, and maximize productivity.

The employed paint crew should be encouraged to report any hazards they encounter at work. If painters see or experience unsafe conditions, they should report them to authorities without feelings of fear or retaliation.

Companies should promote conducting regular safety inspections to identify potential hazards. They should also recognize and reward workers or teams for their significant contributions to workplace safety. Companies should emphasize the importance of safety during company meetings and discussions.

Conclusion

All painters desire to work in a safe and protected environment. Health and safety are some of the biggest issues, and the company’s responsibility is to ensure their employees work in a safe environment. The consequences can be serious and even life-threatening if the company runs an unsafe operation.

Workplace safety is not just a duty required by law but also a moral responsibility on the part of the company. Commercial painters in the Bay Area and elsewhere have families and personal lives outside of their employment, so their health and safety should never be compromised for a paycheck. For that reason alone, putting their safety and well-being at the forefront of the paint service industry is crucial.

If you want to know more about workplace safety, discover more about Custom Painting, Inc.’s services, or schedule painting jobs with us, call us at 925-294-8062 or send us a message. We look forward to working with you!